Lifelong solutions with Benarx Fire Protection

Beerenberg was selected to deliver Benarx Epoxy Fire Protection Boxes for a new offshore production platform bound for Australia. All surveys, production, and installation were completed smoothly and on schedule with the support of our trusted local partner in China.

Fire protection of FPSO valves in Asia

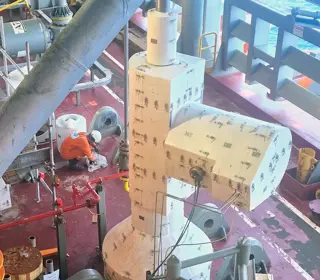

Beerenberg designed and delivered the PFP boxes for this FPSO project using Benarx Epoxy Boxes. Scanning and installation were conducted at the construction yard in Asia. The scanning was performed by Beerenberg, while installation was carried out by local fitters under the supervision of Beerenberg.

Fire protection of valves on FPSO

Beerenberg delivered 320 Passive Fire Protection boxes (74 sets) to a FPSO located offshore in South America. Local fitters installed the Benarx boxes under supervision of Berenberg.

Pre-assembled insulation ensured easy installation at Mongstad refinery

Beerenberg has together with Equinor developed a solution with pre-assembled GRP and aerogel insulation designed for quick and easy installation. The insulation has been installed in several areas at the Mongstad Refinery.

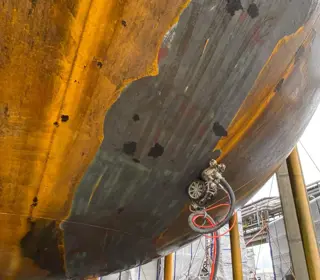

Robotic surface treatment on FPSO in Brasil

Beerenberg and Remotion has successfully carried out offshore hull refurbishment of Equinor’s Peregrino FPSO which is located east of Rio de Janeiro, in the southwest part of the Campos Basin.

Wrapping saved the customer millions

Through an alternative repair method, the customer avoided an extended turnaround. The cost savings in production start-up and simplified solution with wrapping can be estimated at one week's production turnover.

12-day mission with Spiderjet on Kvitebjørn

A robot mission was carried out with Spiderjet on Kvitebjørn on 1,400 square meters

Grating replacement on lifeboat deck at Statfjord C

Replacement of 70 m2 with grating carried out with rope access technique (RAT)

Turnaround Statfjord A, B og C

Beerenberg has extensive experience in performing mechanical services and is experiencing a large growth in maintenance tasks onshore and offshore.

Decommissioning of Gyda

The 18,000-tonne oil platform Gyda has produced its last barrels of oil. Beerenberg assisted in shutting down and preparing the platform for removal.

Robotic surface treatment of industrial tanks

Surface treatment of industrial tanks has traditionally meant extensive manual work, both in the preparation phase and the actual implementations. Now new technological robot solutions can make work more efficient in the oil and gas industry.