Client: FPSO operator

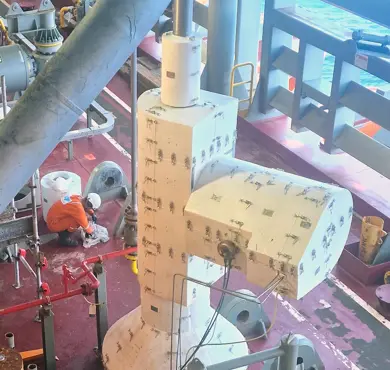

Project type: Fire protection of valves

Location: South America

Scope / Value: 74 items

The challenge

Scanning and designing PFP boxes for this project were challenging due to its complexity and tight construction schedule for actuated valves.

We had a tight schedule for the delivery of PFP boxes from the moment production began to the moment they were completed.

The Solution

Maintaining close communication with the scanning team to ensure high-quality scanning.

Good targeting on clashes thanks to quality scans also ensured similar designed items.

The benefits

We improved both the efficiency and the productivity of the production process. With reduced installation time on site, the scope was completed within the project milestones.

Conclusion

Providing effective communication and instruction to all parties at the outset is one of the most important aspects of making sure the project is completed successfully.

The combination where our design team in Poland can use both scanning, 3D models and GA drawings as basis for the design gives us a flexibility in the projects.

At the same time, it minimize the clash issues during installation, which is crucial for the client in a hectic commissioning phase of the project.