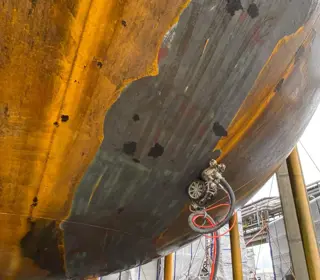

We carry out most of the surface treatment and have extensive experience with corrective maintenance and installation during new construction. Beerenberg offers a total delivery, from pre-treatment with the right tools to the application of the correct paint system.

In our work with surface treatment, we emphasize cost-effectiveness, health, environment and safety (HSE), as well as environmentally friendly solutions.

Industry leading

Beerenberg is an industry leader in the area, and has considerable experience in surface treatment, where we have provided these services since 1979, we carry out all types of surface projects for industry. We have the expertise, competence and experience needed to deliver high-quality surface treatment, which contributes to extended service life.

Sustainable

In addition to extending the lifetime of facilities, surface treatment can also help to reduce the environmental impact. For example, the use of environmentally friendly materials and processes can help reduce emissions of harmful substances.

Corrosion is a significant maintenance risk in the oil and gas industry. It can lead to a reduced lifetime of facilities, increased costs and an increased risk of accidents.

Reliable partner

Beerenberg is then your reliable partner for efficient and sustainable surface treatment. We have the expertise and experience needed to help you extend the life of your facilities and reduce your environmental impact.

In addition to traditional surface treatment, we also deliver solutions within:

We are a leading player in technical cleaning of all types of tanks and pipe flushing offshore and onshore. Get in touch for efficient and safe completion of the job.

With our extensive experience, we carry out technical cleaning and pipe flushing for all types of tanks, both offshore and onshore, and adapt the work for optimized results. We have extensive experience and standardized procedures and processes for entering and cleaning both open and closed systems.

For optimal personnel on board and efficient work carried out on the platform or land plant, we use multi-skilled personnel with both ISO and mechanical competence, in addition to competence in technical cleaning.

Some of the areas in which we have extensive experience and expertise are:

- Mud tanks

- Diesel tanks

- Drinking water tanks

- Process equipment

- Waste oil tanks

- Coolers

- Pipe flushing

Beerenberg provides engineered wrapping services with the aim of extending the lifetime. It's a solution that cuts time, cuts costs, and offers an environmentally friendly alternative to producing new pipes.

The work is carried out by our own personnel with multidisciplinary competence on-site, and it is usually not necessary to mobilize additional personnel. Beerenberg has engineers who calculate each job and work closely with suppliers. The work has a short completion time, which in turn leads to reduced costs.

Wrapping can be used on piping, decks, caissons, beams, truss structures, tanks, and drainage channels. Wrapping is cost-effective in terms of both solution and personnel mobilization. Additionally, it has easy installation and does not require hot work. Wrapping can be applied during operation and requires no maintenance. It is also TR3016 approved and has a lifespan of up to 20 years.