- We have had a significant investment over the past three years to strengthen our position within complementary services to ISO, where mechanical is a service for which we have experienced great demand and see good opportunities for further growth going forward, says VP MMO, Ole Christian Thømt.

More turnarounds

At Statfjord A and Statfjord B, Beerenberg has carried out turnarounds within a broad range of services including insulation, scaffolding, surface, access technology, habitat and tank cleaning. In addition, mechanical services such as cutting, rig assistance, tank work, grating and habitat made up a large part of the assignments.

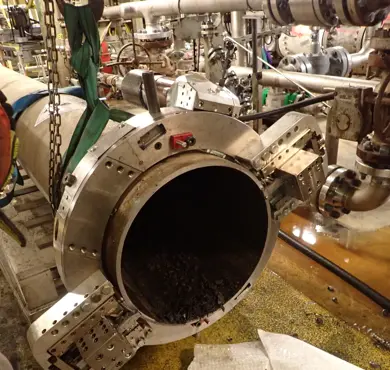

- On Statfjord B, 160 cuts of dimensions up to 30 inches were carried out in connection with pipe replacement. With up to 30 people in rotation, the pipes were initially cut onsite, before they were rigged out by personnel from Apply and Beerenberg and then lifted down onto a boat. The work went on both day and night and was very demanding, as in addition to being large quantities, it required a lot of precision throughout the execution, says field manager FLX Johan Taavo.

At Statfjord A there was also a lot of activity within both ISO and mechanical services.

Both above and below the water surface, several tonnes of old pipes, flanges and valves were cut, dismantled and replaced with new ones, says the field manager.

Aggressive chemicals that cause corrosion and leaks are a challenge at facilities and must be regularly maintained.

"Flange surfaces on internal tanks become uneven over time due to rust and these were flattened with the help of belzona, i.e. liquid steel that hardens, so that they become smooth and completely sealed and thus prevent damage and leaks from occurring," he says.

Solution-oriented environment

Head of the mechanical department, Bertil Bargård, is satisfied with the increased demand for mechanical services and praises the efforts of the operators and engineers.

Ownership from planning to execution rests heavily with our mechanics. There are complex operations that are carried out, and require a solution-oriented environment to ensure the best possible implementation, he says.

Good solutions often come with experience

-One of the success factors for Beerenberg has been to use mechanics with long experience in leading positions in the projects to bring out the good solutions. We are already in the planning phase of a new audit stop, this time at Statfjord C, where we will use the same successful model to ensure another good project, says Bargård.

Beerenberg as total supplier

Beerenberg feels that, to a greater extent than before, customers are demanding a total solution with a focus on a safe, sustainable and reliable implementation with simple and seamless interfaces.

- For us, this means in practice that within our well-established and efficient implementation model, combined with a workforce with high and interdisciplinary competence, we offer more services to our customers, concludes Thømt.