Can perform all surface maintenance

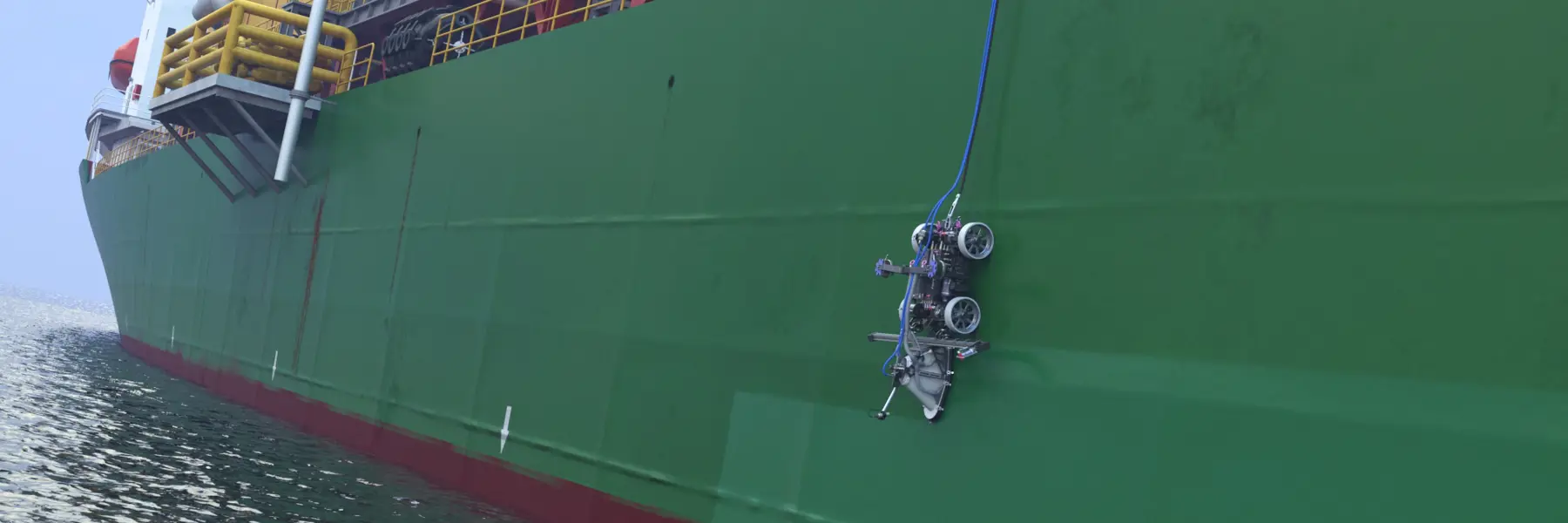

Remotion´s latest robot is a complete surface maintenance system where all the sequences are robotic, saving valuable time and resources for FPSOs at sea.

Beerenberg´s Remotion has been awarded a contract by Aker BP for robotic fabric maintenance of the hull on Alvheim FPSO. The contract marks a milestone in the development of a unique robot that can do all surface maintenance work, saving valuable time and resources.

Fabric maintenance of hull surfaces can be demanding when it comes to a FPSOs at sea. The Alvheim FPSO is a floating Production Storage and Offloading vessel that produces crude oil and gas. Crude oil is stored in tanks and transported directly to the shuttle tanker, and Gas is transferred onshore through pipeline.

The offshore operation will start in April 2023.

Collaboration project

The contract is a result of several years with research and development in collaboration with the client. During the development phase, Remotion created a complete system for robotic fabric maintenance where all the sequences are robotic. On Alvheim FPSO, the scope is 5500 m2 with vertical hull surface, where all old coating will be removed, surface profile controlled, and a new three layers coating system will be applied.

Morten Urrang in Remotion is excited about the developments.

“It is fantastic to finally see the results of many years development now that we move on to the operational phase,” says CEO of Remotion, Morten Urrang

High efficiency

Traditionally, this is demanding maintenance work that includes both scaffolding and working above open water with strict weather conditions. Based on simulations, the client had estimated 3 m2 of complete system each day, with a total of 5500 m2 to be maintained. With the added need for good weather days in the North Sea, the scope was almost reconned as a Mission Impossible project. With new technology, the project is now aiming for more than 60 m2 per day.

More sustainable

In addition to significantly higher efficiency, the project and the technology also have several other advantages; no emissions of paint residues, contributing to the United Nations Sustainable Development Goals 12 and 14, better HSE profile with robots handling noisy and dangerous tools, less personnel onboard and more precise quality of surface coating. The operation will be carried out by a carefully trained team consisting of personnel from Remotion and Beerenberg.

Maintenance robots in demand

Several other technology projects are also experiencing great interest from returning and potential new clients. The pipe robot system Icarus has been awarded a contract with Equinor in Brazil for work onboard Peregrino B. Equinor has also awarded Remotion a 4-month contract for work onboard Norne FPSO, where will we continue underwater hull maintenance operations.

“We are now working on establishing a solid product portfolio of technology, much is already in place, but some adaptations are being made to better meet the needs we have identified in the market.” CEO of Remotion, Morten Urrang.